The construction industry is at a turning point. Projects are becoming larger, denser, and more complex, while schedules continue to tighten. At the same time, expectations around accuracy, documentation, and accountability have never been higher. Traditional surveying and inspection methods are struggling to keep pace with modern Building Information Modeling workflows, often leaving teams working with outdated or incomplete site data.

As drone pilots and construction technology specialists who work extensively with the Skydio X10, we have seen firsthand how advanced autonomous capture is changing the way construction teams collect, analyze, and act on spatial data. The X10 is not just another drone; it represents a meaningful shift toward faster, safer, and more reliable reality capture across the construction lifecycle.

The Construction Data Gap

Modern construction relies on BIM as the backbone for design coordination, sequencing, and execution. These digital models are meant to represent a single source of truth, allowing teams to identify clashes, plan workflows, and track progress across multiple trades. The problem is keeping those models aligned with reality as the project evolves.

As-built conditions change daily. Manual surveying methods, while accurate, are slow, labor-intensive, and expensive. By the time measurements are processed and shared, conditions on site may already be different. This delay creates blind spots that often surface later as rework, delays, or disputes.

Drone-based 3D modeling addresses this gap by capturing comprehensive site data quickly and repeatedly. But effectiveness depends heavily on the platform being used. The Skydio X10 stands out because it was designed for complex, obstacle-filled environments like active construction sites.

Why the Skydio X10 Is Different

The defining feature of the X10 is autonomy. Powered by advanced spatial AI and six navigation cameras providing 360-degree obstacle awareness, the drone can safely operate in dense environments filled with cranes, scaffolding, power lines, and moving equipment. Instead of requiring constant manual piloting, the system understands its surroundings and navigates intelligently on its own.

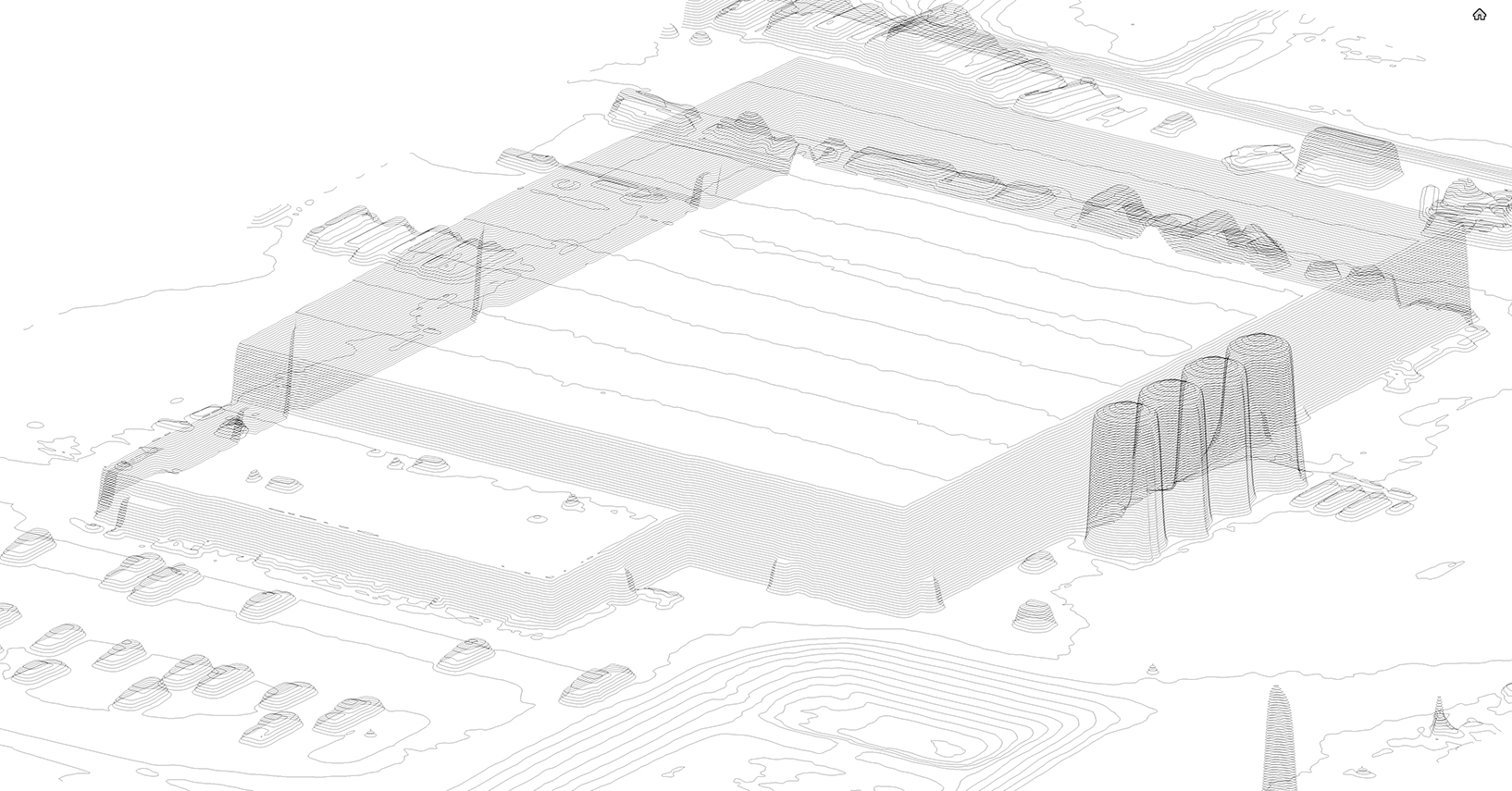

For construction teams, this autonomy translates directly into efficiency and reliability. In 3D Capture mode, operators define the scan volume by setting floor and ceiling heights and placing virtual pillars around a structure. The X10 then autonomously plans and executes a flight path, ensuring complete coverage from all necessary angles. The drone builds an internal spatial model as it flies, adapting its path to capture complex geometry without pilot micromanagement.

Sensor quality is another major differentiator. The VT300-Z payload combines a 64-megapixel narrow camera, a 48-megapixel telephoto lens, and a radiometric thermal sensor. For low-light or interior work, the VT300-L features a one-inch sensor with integrated LED illumination. These custom-engineered optics deliver the resolution and consistency required for accurate photogrammetry, inspection, and analysis.

Perhaps most impactful for field operations is onboard modeling. During 3D scans, the X10 generates preview models and coverage heatmaps directly on the controller. This allows crews to verify data completeness immediately, identify gaps, and correct issues before leaving the site. It removes the common frustration of discovering missing data days later during office processing.

Applications Across the Construction Lifecycle

We deploy the Skydio X10 from pre-construction through project closeout, with each phase benefiting in different ways.

Pre-Construction Surveying:

Accurate topographic data is essential before breaking ground. Using automated mapping flights, the X10 can survey large sites in a fraction of the time required by traditional methods. Orthomosaics and digital elevation models integrate directly into BIM workflows, giving designers current conditions rather than relying on outdated surveys.

Earthwork and Foundations:

During grading and excavation, volumetric accuracy matters. Regular drone scans generate point clouds and 3D models that support precise cut-and-fill calculations, stockpile tracking, and progress verification. Frequent flights allow teams to validate contractor quantities and identify discrepancies early.

Structural Progress Tracking:

As structures rise, maintaining accurate as-built records becomes critical. The X10’s autonomous navigation excels in complex structural environments, capturing complete documentation of steel, concrete, and core elements. Comparing these scans against design models quickly reveals deviations before they compound into larger issues.

Quality Assurance and Inspection:

High-resolution visual and thermal data supports detailed inspections of facades, roofing systems, and mechanical installations. Thermal imaging helps identify insulation gaps, moisture intrusion, and air leakage while remediation is still feasible, rather than after occupancy.

As-Built Documentation:

At project completion, comprehensive 3D scans provide owners with reliable digital twins for operations, maintenance, and future renovations. Accurate as-built data reduces guesswork and costly field verification years down the line.

Seamless Integration with Existing Workflows

The value of drone capture depends on how easily data integrates with existing construction technology. The X10 exports imagery compatible with leading photogrammetry platforms such as Pix4D, DroneDeploy, Bentley iTwin Capture, and Autodesk ReCap. Point clouds, meshes, and orthomosaics are delivered in standard formats that slot directly into BIM and GIS environments.

This interoperability allows teams to choose the right processing tools for each project without being locked into proprietary ecosystems. Cloud-based platforms further enable collaboration, giving designers, managers, and owners access to up-to-date site conditions regardless of location.

Autonomous Safety in Dynamic Environments

Active construction sites are unpredictable. Obstacles move, lighting changes, and site layouts evolve daily. The X10’s spatial AI does more than avoid collisions; it actively understands the environment and reroutes intelligently when conditions change. This capability reduces pilot workload and enables safe operation in scenarios that would be difficult or risky for manually flown drones.

NightSense technology extends operations into low-light or nighttime conditions using infrared illumination for navigation. This allows documentation outside standard working hours without disrupting crews or surrounding communities.

Onboard Validation That Saves Time and Money

Immediate data validation is one of the X10’s most practical advantages. Coverage heatmaps and preview models make it clear whether all required surfaces were captured. If gaps appear, they can be corrected on the spot.

This capability significantly reduces costly remobilizations, especially on large or remote projects. For recurring progress scans, it also ensures consistency across datasets, which is essential for reliable comparisons over time.

Measuring the Return

The return on investment from autonomous drone capture is tangible. Documentation time is reduced by 70 to 80 percent compared to traditional surveying methods. More frequent data collection enables earlier detection of issues, reducing rework and schedule impacts. Improved safety outcomes come from minimizing the need for personnel to access hazardous areas.

Equally important is communication. Visual data from drone-captured models provides clarity that traditional reports cannot, helping align stakeholders, support decision-making, and build confidence in project execution.

Looking Ahead

Construction is moving toward a future that is increasingly digital, automated, and data-driven. Reality capture will play a central role as AI-driven analysis begins to automatically flag discrepancies, verify installations, and predict risks. Autonomous systems like the Skydio X10 are laying the groundwork for that future by delivering consistent, high-quality datasets at scale.

For teams focused on building efficiently, safely, and accurately, advanced drone-based 3D modeling is no longer optional. The Skydio X10 enables construction professionals to close the gap between design and reality, transforming how projects are documented, managed, and delivered.

The future of construction is already taking shape, and with tools like the X10, teams are not just keeping up with it. They are actively building it.

Get in touch