The reality is stark: commercial solar systems experience a median annual degradation rate of 0.8%, nearly double the projected 0.4% rate. Without proactive monitoring, that efficiency loss translates directly into diminished returns on what should be a 25-year investment. Infrared thermography has emerged as an indispensable diagnostic tool, fundamentally changing how we approach solar array maintenance and performance optimization.

The Invisible Problem with Visible Consequences

Solar panels generate excess heat rather than power when components malfunction. The challenge lies in detection: most issues affecting solar performance are invisible to the naked eye. A cell operating 20°C hotter than its neighbors might look identical during a visual walkthrough, yet that temperature differential signals significant power loss and potential safety hazards.

Thermal imaging cameras detect infrared radiation emitted by objects, with radiation levels corresponding to surface temperature. When applied to photovoltaic systems, this technology reveals thermal signatures of failing components, damaged cells, and electrical faults that would otherwise remain hidden until causing catastrophic failure or measurable production losses.

In our operational experience, thermal inspections routinely identify issues that monitoring systems and production data fail to catch early enough to prevent revenue loss. We've scanned large commercial arrays and found cells operating 20°C hotter than surrounding panels, situations where clients hadn't noticed performance drops yet but were weeks away from major failures.

Common Defects Revealed Through Thermal Analysis

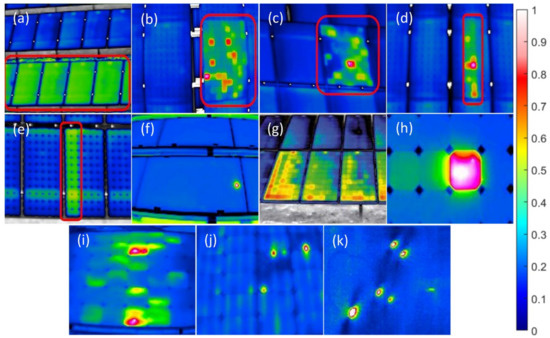

Hotspots and Cell Failures: Individual cells fail due to manufacturing defects, micro-cracks, or external damage, creating distinct hotspots in thermal imagery. Temperature differentials of 5 to 10°C warrant monitoring, while differentials exceeding 10°C indicate problems requiring immediate action.

String and Array Failures: When entire strings go offline due to blown fuses, tripped breakers, or wiring issues, thermal mapping reveals rows of panels running cooler than the rest of the array, pinpointing electrical disconnections that silently erode production capacity.

Delamination: Layers within panels separate, creating air gaps that reduce heat transfer. Delaminated areas appear cooler than properly bonded sections, indicating structural degradation that will worsen over time.

Junction Box and Connection Issues: Loose connections, corroded terminals, and improperly sealed junction boxes create resistance manifesting as elevated temperatures. These issues pose both performance and fire hazards.

Shading and Soiling: Debris accumulation forces affected cells into reverse bias. These cells not only stop producing electricity but actually consume power from functioning cells, appearing as distinct hot areas in thermal scans.

Bypass Diode Failures: When bypass diodes fail, they cause localized overheating. Thermal imaging easily spots these failures, which otherwise require invasive electrical testing to diagnose.

The Aerial Advantage: Drone-Based Thermal Inspections

Drone-based aerial infrared thermography has revolutionized solar inspections, offering speed, safety, and comprehensive coverage impossible with manual methods. Recent industry data shows drone adoption in the solar sector surged 45% from 2023 to 2024, driven by advances in AI analytics and thermal imaging technology.

The numbers tell the story: drone-based thermal inspections typically require as little as 10 minutes of flight time per megawatt, compared to manual methods requiring 2 to 5 hours per megawatt. For a 50 MW installation, this means completing an inspection in a single workday versus 6+ weeks of manual work.

We deploy drones equipped with high-resolution thermal cameras capturing both infrared and visible spectrum imagery simultaneously. Advanced systems maintain flight speeds up to 15 to 20 mph while capturing thermal data precise enough to identify issues at the individual cell level. Automated flight planning ensures systematic coverage with georeferenced thermal images that precisely locate every detected anomaly.

Drone operations keep technicians on the ground, eliminating risks associated with climbing on structures, working at heights, or navigating around live electrical equipment. Beyond speed and safety, aerial thermography provides perspectives impossible from ground level, identifying patterns across multiple arrays and detecting problems in panels difficult or dangerous to access manually.

Financial Impact: The ROI of Thermal Inspections

For commercial solar operators, every percentage point of lost efficiency directly impacts the bottom line. Industry research indicates that anomalies in photovoltaic systems cause an average 3.13% annual energy loss across global solar fleets.

Consider real-world scenarios: a 50 MW solar farm experiencing 4.9% power loss from undetected inverter faults could lose approximately $245,000 annually at current electricity rates. A 20 MW installation with tracker issues might forfeit $94,000 yearly in lost production.

Recent industry analysis shows that drone inspections saved an estimated $788 million annually across photovoltaic systems in 2025, up from $435 million in 2020. These savings stem from reduced labor costs and recovered production losses, averaging approximately $2,100 per megawatt inspected.

One solar asset owner documented annual savings of $476,104 by repairing defective modules that likely would not have been discovered during traditional on-foot inspections. The panels remained under warranty, meaning repairs cost nothing beyond labor while preventing years of degraded production.

Thermal inspections cut labor costs by up to 75% compared to manual methods. For that 50 MW site inspected in 5 hours via drone versus 50 days manually, labor savings alone exceed $42,000 per inspection. When combined with recovered production from identified and repaired anomalies, the financial case becomes overwhelming.

Implementation: Professional Inspection Protocols

Effective thermal inspection requires more than flying a drone with a thermal camera. Professional-grade inspections follow rigorous protocols to ensure accurate, actionable results.

Site Evaluation and Planning: Before conducting thermal scans, we perform comprehensive site evaluations, reviewing system documentation, design specifications, previous inspection reports, and maintenance records. We assess environmental factors such as shading patterns, panel orientation, and site access.

Optimal Inspection Conditions: Thermal accuracy depends on proper environmental conditions. We conduct inspections when solar irradiance exceeds 600 watts per square meter, following IEC TS 62446-3 standards. Inspections typically occur during midday hours when panels operate under load and thermal signatures are most pronounced.

Systematic Data Capture: Drones follow automated flight paths capturing overlapping thermal and visual imagery of every panel. We use radiometric thermal cameras that record precise temperature data for each pixel, enabling detailed post-flight analysis.

Advanced Analysis and Reporting: Modern AI-powered analytics process thousands of thermal images in minutes, automatically detecting and classifying anomalies. Comprehensive reports include interactive maps with each anomaly georeferenced, paired thermal and visual imagery showing fault types, temperature differential measurements and severity classifications, and estimated annual kilowatt-hour and revenue losses for unresolved issues.

Beyond Panels: Comprehensive System Assessment

Comprehensive assessments must examine the entire balance of system. Inverters, combiner boxes, transformers, and electrical connections all generate thermal signatures indicating their operational status.

Inverter thermal scans compare side-by-side units to identify units operating abnormally hot, suggesting internal component failures. Combiner boxes are checked for loose connections, corrosion, and improper sealing. Electrical connections throughout the system receive scrutiny for resistance heating indicating loose or corroded connections that can create arc flash hazards.

For installations with solar tracking systems, thermal imaging reveals mechanical issues through uneven heating patterns across panels that should receive identical sun exposure.

The Path Forward

As commercial solar installations continue scaling to meet renewable energy targets, the role of infrared inspection will only grow more critical. The industry is moving toward continuous monitoring rather than periodic inspections. Automated drone-in-a-box systems can conduct regular thermal surveys without human intervention, providing near real-time visibility into array health.

Integration with asset management platforms will create closed-loop systems where thermal anomaly detection automatically triggers maintenance work orders, parts ordering, and warranty claim processes.

For commercial solar investors, operators, and asset managers, the message is clear: thermal infrared inspection is no longer optional. It's a fundamental requirement for protecting solar investments, maintaining peak performance, and ensuring the financial returns that justify these substantial capital deployments. Every commercial array deserves regular thermal assessment to catch problems early, validate warranty coverage, and maximize energy production across the system's 25-year-plus operational life.

Get in touch